Steel Road Plates Fundamentals Explained

Steel Road Plates Fundamentals Explained

Blog Article

Steel Road Plates Things To Know Before You Buy

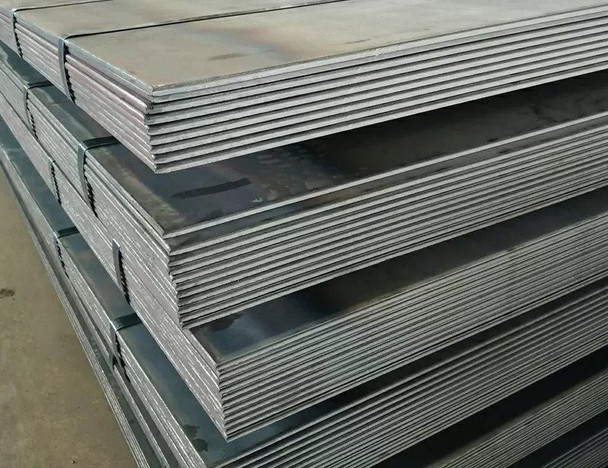

Steel plates are give an excellent, short-lived option for covering harmful holes on a construction website. These heavy-duty, durable plates allow roadways to return to service so that building and construction can continue. Below we check out the layout details and ideal method setup recommendations. These plates can be made use of to make sure that roads can still be made use of whilst various other stages of work proceed.

They supply an ideal concession for maintaining lanes, whilst job proceeds overnight and at weekends. They are typically seen when excavations have actually started as an onset of construction or repair work projects. These plates are created to hold up against heavy-duty usage on active roads. They include an akti-skid coating and are readily available in a variety of colour coatings - Steel road plates.

The weights begin from roughly 300kg and conventional road plates have a thickness of either inch or inch. The capability to be bolted to the road.

The Definitive Guide for Steel Road Plates

Hinged versions for fast accessibility to the excavation or routine accessibility, e.g. driveways. Composite plates, which can accommodate different sizes of trench. Skid-resistance for improved car, pedestrian and site employee security. Steel road plates can be set up rather swiftly, yet they are heavy. Consequently, they must be installed making use of a forklift or crane.

Examine for variation by website traffic loading from the outset plates need to constantly resist displacement. Check that the plates do not provide a risk to any kind of sort of roadway customer and can be used by all road customers and lorry kinds, including pedestrians, bikers and motorcyclists. Create a regular inspection and upkeep to ensure that performance remains risk-free and optimal.

Fix home plates correctly at all times. Mechanical lifting makes certain that home plates are installed properly and safely. The right plates ought to be ideal for the wanted function Consider proper security areas, especially when planning setup. The weight of the plates can cause turning in the building and construction area or throughout neighbouring carriageways/ footways.

If a ramp is created by the roadway layers, after that alerting indications for pedestrian and road users are required. Constantly a conduct complete site study, and take the specialist suggestions of an architectural engineer.

Steel Road Plates Can Be Fun For Anyone

In order to enhance safety and security, there are a number of requirements and sector papers leading their usage in construction job zones. Steel plates have to be taken care of in place to avoid movement.

Steel Road Plates Things To Know Before You Get This

Along with being securely touching the pavement, they should be either pinned, recessed right into the sidewalk, or protected with asphalt wedges around the perimeter. Pinning right into the pavement entails driving pins into the pavements along the edges of the steel plates to avoid motion. Recessing includes cutting out the area where the steel plate will be positioned.

This Steel road plates leads to the steel plate being flush with the sidewalk. In enhancement, when numerous steel plates are used and butt up to each other, they must be bonded together at the longitudinal joints. Steel plates can be very unsafe, especially when they are damp, unless they have an anti-skid finish applied.

Covering steel plates with a material that increases rubbing aids motorcyclists and bicyclists retain control, specifically in wet climate. Conditions which minimize sidewalk rubbing in job areas are of particular problem to motorcyclists and bicycles. A typical danger in steel plate installations takes place when the individual fails to build correctly tapered ramps from the roadway to the sides of the steel plate( s).

6 Simple Techniques For Steel Road Plates

It poses a significant risk to motorcyclists and bicyclists that can quickly shed control when they call the abrupt/steep tapered ramp and the steel plate. Effectively conical ramps allow customers to securely cross over the steel plates. Tapers for steel plates are usually constructed of asphalt. The taper sizes vary from One state to another and generally variety from 20 to 1 to 120 to 1 (Steel road plates).

Department of Transportation's Federal Freeway Administration (FHWA) requires that transverse sidewalk joints, which cause a bump, should be tapered at 60 to 1 (5 feet straight for every 1 inch of vertical altitude distinction). Select the appropriate dimension. Ensure sufficient overlap. Normally, steel plates have to extend at least one foot beyond the sidewalk opening onto firm ground.

7 Simple Techniques For Steel Road Plates

Welding is made use of when more than one steel plate is utilized and they butt up to each other. Plates should be countersunk when needed due to uneven streets.

His history consists of the construction, examination, find out more.

These sturdy steel plates play a vital role in boosting building and construction security, offering momentary roadways, and making sure smooth operations on different job sites. As a construction devices provider, their value can not be overstated.

Report this page